“We believe in linear drives for long-term productivity solutions,” said Christian Thönes, Gildemeister board member. with a positioning accuracy of less than 4µm, which increases productivity by 25 percent, the company reported. For example, the DMC 60 H linear machine’s linear drives provide 1G acceleration and speeds up to 100 m/min. Rüdiger Kapitza, chairman of Gildemeister Group AG, Bielefeld, Germany, the parent company of DMG, pointed out during the press conference that the cost of linear drive motors has increased significantly because of price hikes for rare earth materials, but the technology is essential for boosting productivity while enhancing accuracy. At capacity, the new facility will produce up to 100 units per month, the company reports.ĭr. Next year, the plant will begin building DMG-type machines, he added. factory in Davis, Calif., will start at the end of July.

Ltd., Nagoya City, Japan, indicated that production of HMCs at the company’s new 200,000-sq.-ft. Masahiko Mori, president of Mori Seiki Co.

DMG森精機20200623113735562_Data.jpg)

The latter is least performed primarily because it requires more programming effort.Īlthough a 5-axis machine typically has a high initial cost, it eventually reduces costs by requiring fewer fixtures and cutting tools, shortening lead times and enabling higher flexibility and machine utilization compared to 3- and 4-axis machines, according to Zanth and Bauhor.Īt the Feb. They noted that end users perform 3+2 machining (5-axis positioning) on 73 percent of the 5-axis machines, 5-sided machining on 22 percent and 5-axis simultaneous machining on 5 percent. Workers build a machine at Deckel Maho Pfronten, the largest plant of the Gildemeister Group.

The DMG/Mori Seiki open house at the Deckel Maho Pfronten factory featured 60 machine tools and attracted large crowds during the 5-day event. Mirroring the market, 24 of the 38 milling machines at the open house were 5-axis. Their presentation noted that 5-axis machining is a growing market, with about 60 percent of the milling machines sold in 2011 being 5-axis. The seminar presenters included Michael Zanth, sales manager, and Otto Bauhor, technical sales, for Deckel Maho Seebach (Germany) GmbH. That includes using one machine instead of multiple machines to perform what is needed and thereby reducing the required work space. 7 and focused on the savings and benefits of using a 5-axis machine.

Dmg mori full#

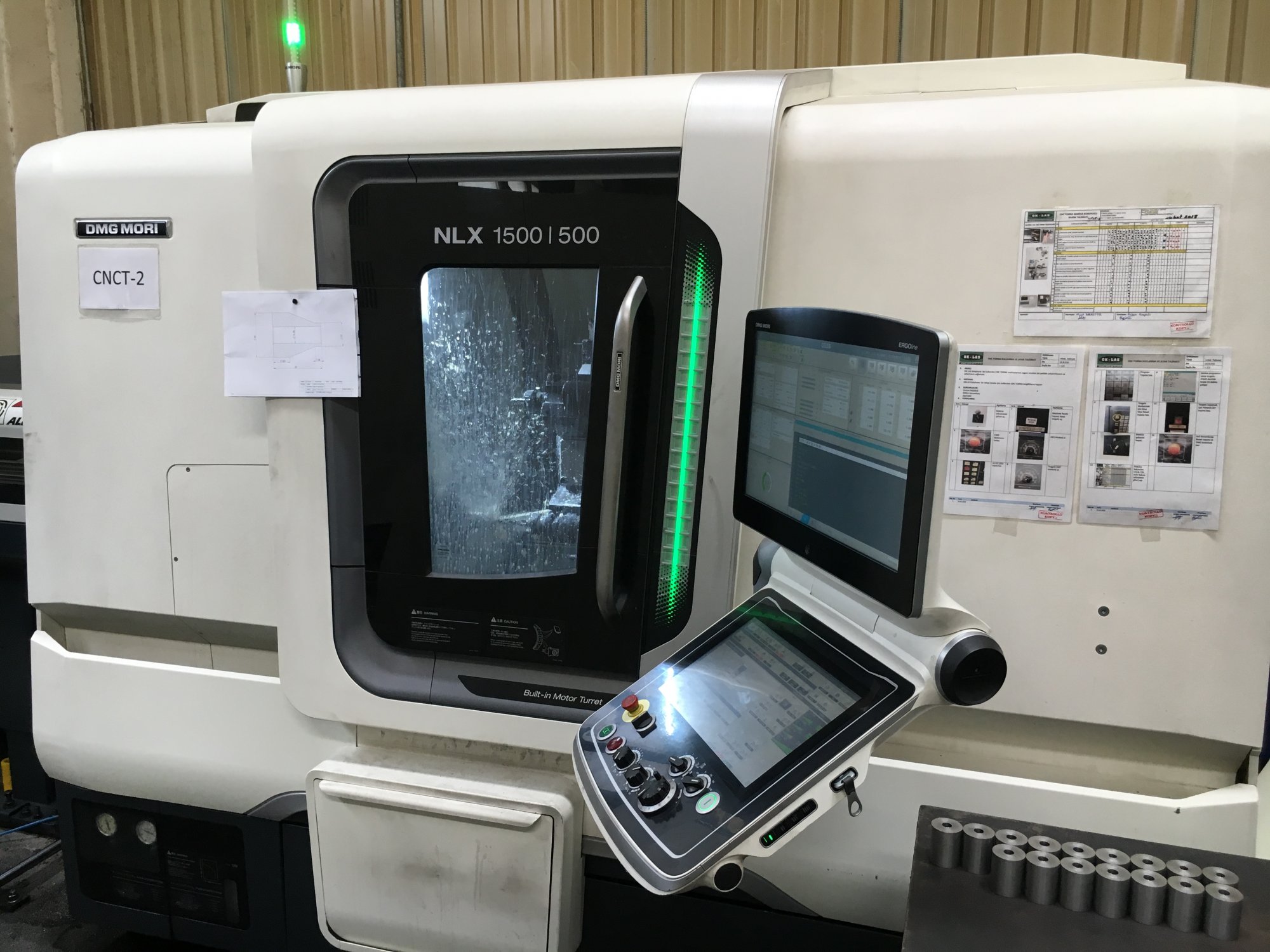

“The Full Range of Modern 5-axis Machining” seminar took place Feb. The open house featured 10 technology seminars. The machine tool builder exhibited 60 machines, with six being world premieres: the 4-axis CTX beta 800 4A turning center, the DMC 60 H linear horizontal machining center with optional swivel rotary table for 5-axis machining, the 5-axis DMU 85 FD monoBLOCK mill/turn machine, the 5-axis DMC 65 monoBLOCK universal machining center, the 5-axis DMU 80 eVo with pallet changer and the NHX4000 HMC for machining workpieces up to 24.8"×35.4". 7 to 11 and reportedly drew more than 5,000 industry professionals from around the world. For the first time as a combined company, DMG/Mori Seiki hosted the open house held annually at the Deckel Maho Pfronten (Germany) GmbH plant.

0 kommentar(er)

0 kommentar(er)